Proximity sensors play a crucial role in industrial automation, manufacturing, automotive applications, and various other industries by enabling non-contact detection of objects. A reliable proximity sensor manufacturer contributes significantly to enhancing equipment longevity and performance by designing high-quality sensors with superior durability, accuracy, and adaptability. These manufacturers employ cutting-edge technology, robust materials, and innovative engineering techniques to ensure their sensors provide optimal performance in demanding environments. One of the most significant ways a manufacturer enhances equipment longevity is by producing sensors with high durability and resistance to harsh conditions. Industrial environments often expose equipment to extreme temperatures, moisture, dust, vibrations, and corrosive substances. A top-tier proximity sensor manufacturer uses materials like stainless steel, reinforced polymers, and high-quality sealing technologies to create sensors that withstand these challenges. By preventing direct contact between machinery components, these sensors reduce wear and tear, thereby extending the lifespan of critical equipment.

Another crucial aspect is the precision and reliability of proximity sensors. High-quality sensors manufactured with advanced signal processing algorithms ensure accurate detection, minimizing false triggers and erratic responses. In automated manufacturing, even a minor sensor malfunction can lead to production delays, defects, or costly downtime. Manufacturers enhance performance by incorporating high-frequency detection, improved electromagnetic shielding, and temperature compensation features, proximity sensor supplier allowing the sensors to function optimally in fluctuating environmental conditions. Energy efficiency is another key factor that a reputable proximity sensor manufacturer focuses on to improve overall equipment performance. Many modern sensors are designed with low power consumption capabilities, making them ideal for battery-operated systems or energy-conscious industrial setups. This not only reduces operational costs but also ensures sustainable performance in industries that require round-the-clock monitoring and automation. Additionally, integrating smart sensor technologies such as IoT connectivity and self-diagnostics helps prevent failures before they occur, further enhancing system reliability and reducing maintenance costs.

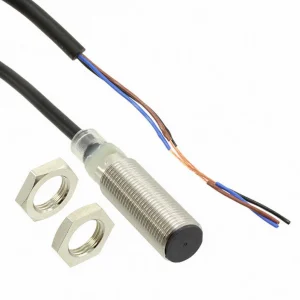

Adaptability is also a major factor in ensuring that equipment operates efficiently in various conditions. Proximity sensor manufacturers develop a wide range of sensors, including inductive, capacitive, ultrasonic, and photoelectric sensors, to cater to different applications. For example, inductive sensors are perfect for metal detection in heavy machinery, while capacitive sensors can detect plastic, glass, or liquid levels. By offering diverse sensor solutions, manufacturers help industries select the most suitable sensor type, ensuring optimized performance for their specific needs. Furthermore, manufacturers continuously invest in research and development to innovate and refine sensor technology. The incorporation of artificial intelligence AI and machine learning ML into proximity sensors is revolutionizing industrial automation by enabling predictive maintenance and real-time performance monitoring. These advancements help industries achieve higher efficiency, prevent equipment failures, and optimize workflow, ultimately leading to increased productivity. A omch proximity sensor manufacturer plays a vital role in extending equipment longevity and enhancing performance by producing durable, high-precision, energy-efficient, and adaptable sensors.